Add a unique design detail. Bring visual continuity to a complementary solid surface. Or tailor a top specific to your work style. There is no better way than by selecting the right edge profile. Wood Welded® Butcher Block tops are available finished in a variety of stock and custom edge profiles, including special order options.

Special Order - White Ash - Butcher Block Counter Tops

WHITE ASH -BUTCHER BLOCK COUNTERTOPS - Edge Grain

- True "Edge Grain" countertops are where the wood is first cut into long staves, then the staves are turned on their edge so that the edge grain is facing up on the top, the face grain now on the side. The staves are then glue laminated under high pressure. This process is used because the edge grain of wood is harder to split than the face grain. A true Butcher Block style countertop has the edge grain facing up making it much more durable and harder to split than a face grain or plank countertop.

Solid Wood Counter Tops

MORE INFORMATION

- Our Butcher Block Counter Tops have no butt-joint or finger-joints exposed on the front edge or back edge. Giving a clean one-piece edge to your countertop.

- Careful gluing and curing methods produce the finest quality. One of the world’s largest manufacturers of Butcher Block products, Bally Block, has been producing the finest quality for over 120 years. Using select kiln-dried wood, local fine wood craftsmen build Butcher Blocks, counter tops, and specialty tables of durability and distinction. Their careful gluing and curing methods yield the most beautiful hard hard-wearing blocks on the market.

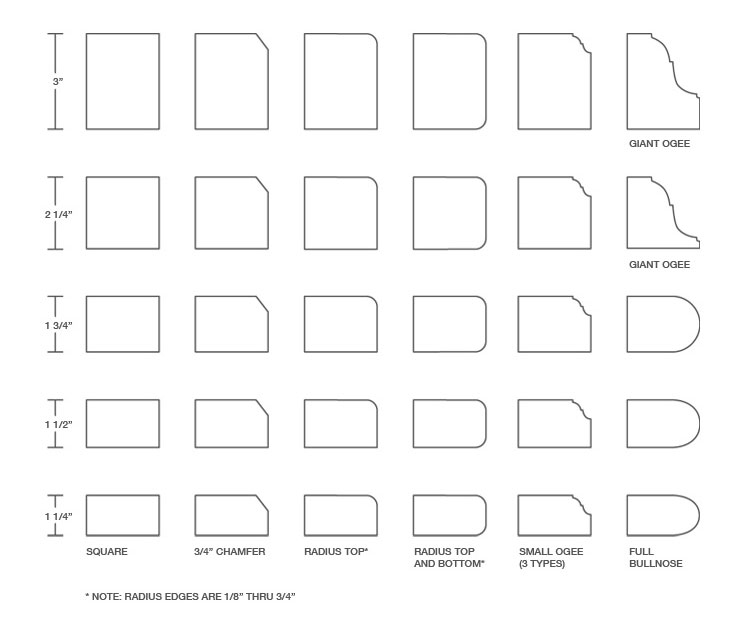

Edge Profiles

Standard Edge Profile

The Square edge profile is standard on most Wood Welded products including countertops, kitchen islands and workbench tops. If the square edge does not fit your design or taste, custom edge profiles can be specified at the time of ordering.

Custom Edge Profile

Radius, bullnose and ogee edges are also available with our stock fabrication equipment. These are considered custom and can be specified with your dealer or distributor at the time of ordering.

Special Order Edge Profile

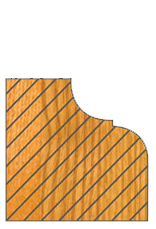

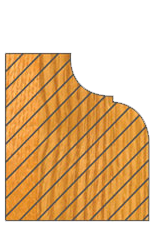

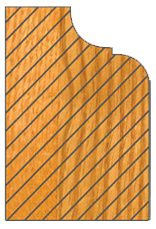

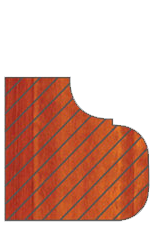

Have a special edge request? Our flexible fabrication methods allow us to offer virtually any edge profile. We use high-quality Amana woodworking router bits to cut edge profiles. Shown here are the “Classical Cove and Bead” (Amana) and the “Classical Cove and Bead with a Double Roundover” (Memphis) on various thicknesses. These are designated as a custom edge profile and should be specified at the time of ordering.

Amana Edge 1 1/2″

Amana Edge 1 3/4″

Amana Edge 2 1/4″

Memphis Edge 1 1/2″

Memphis Edge 1 3/4″

Memphis Edge 2 1/4″

Edge Profiles Relative to Thickness

The diagram below illustrates edge profiles relative to different thicknesses of butcher block.

Finish Options

Standard Factory Finishes

Durakryl 102®

Our standard finish on countertops, islands, commercial foodservice tops, workbench tops and locker bench seats is DURAKRYL 102, a proprietary urethane-based satin finish. It is food-safe, resistant to stains and most solvents, and cleans up with warm soapy water. Stubborn spills or stains can be removed with nail polish remover.

DURAKRYL 102 resists marring, is moisture resistant, and meets the test requirements of the Kitchen Cabinet Manufacturing Association (KCMA).

The formulation, when cured, leaves an inert film. The constituents of the cured film have been tested by an independent university laboratory and found to be non-toxic. The film is approximately 95% cured during the manufacturing process and 100% cured within two weeks of manufacture. Only inert film is present on installed tops as manufactured.

DURAKRYL 102 has been tested against many common household and industrial products. The results are listed as passed or no effect (P) and failed or moderate to severe effect (F). A moderate effect would be a softening or discoloration of the finish.

Rubbed Oil

Our standard finish on butcher block cutting boards, chopping blocks and specialty boards is mineral oil. Mineral oil has been the traditional finish used by butchers for over a century to keep their blocks looking and functioning at their best.

All Wood Welded® butcher block products with a rubbed oil finish are fabricated with a generous coating of oil. Mineral oil penetrates the block, thus sealing the pores of the wood, inhibiting moisture penetration and extending the life of the block.

While mineral oil is a fine finish, it does require occasional maintenance. It is possible that the block may have dried during storage and shipping, thus we recommend re-oiling the board prior to its first use. Maintenance thereafter depends upon the environment and the amount of use. When the block begins to look dry and “chalky”, the block should be re-oiled. Pure mineral oil can be purchased at your local drug store. We DO NOT recommend using any oil made of vegetable or animal fats, as these types of oils run the risk of going rancid and can be a health issue.

Wood Welded has also developed, Emmet’s Elixir, a product specifically for oiled cutting surfaces. Emmet’s Elixir is an all-natural anti-microbial cutting board conditioner made of food-safe mineral oil and beeswax.

Unfinished

Wood Welded butcher block is also available unfinished. Unfinished butcher block comes without our standard 1-year warranty. The reason for this is that wood is hygroscopic, meaning its moisture content will constantly fluctuate. A finish stabilizes the moisture content of the block. Without finish, the wood can end-check and warping can occur. If you choose to take delivery of an unfinished butcher block, the quality of the block is every bit as high as our finished block, and as long as a finish is applied immediately, the block will function as intended. Note: the longer the block goes unfinished, and the greater the difference in environment, the greater the chance the block will develop problems. This is natural to wood and is not a manufacturing defect.

Aftermarket Finishes

Emmet’s Elixir Wood Conditioner

Emmet’s Elixir is an all-natural, anti-microbial formulation of beeswax and food-safe mineral oil that is ideal for our unfinished and rubbed oil butcher block products. This easy-to-use, cream-based conditioner provides a protective sealant and restorative luster. It is designed to penetrate the wood and give the surface a seal of wax to prolong the period of time between re-oiling. The clean rosemary-lemon scent is also an anti-microbial agent.

Emmet’s Elixir Wood Conditioner is an aftermarket product. It is the only cutting board conditioner certified by the National Sanitation Foundation (NSF®), making it approved for use in commercial foodservice operations. Available in 4 oz., 16 oz., and 1 gallon units.

Emmet’s “Good Stuff”® Wood Finish

Emmet’s “Good Stuff” is an easy-to-use urethane gel that is compatible with our DURAKRYL 102 finish. Developed as an aftermarket finish to reseal areas that have been cut or modified for custom installation by a contractor; to touch up a worn block; or to completely refinish a top.

Formulated with fast drying synthetic oils, Good Stuff is designed for easy application with a lint-free cloth or rag. It’s crystal clear satin finish will enhance the natural beauty of wood while offering an outstanding protective finish that is resistant to moisture and most solvents. Please follow the instructions on the can for application instructions.

Installation Tips

For the best results in the installation of your butcher block surface, it is important to read and follow these instructions. Wood is a hygroscopic material, it continues to gain and lose moisture throughout its existence. Following these simple instructions will ensure that you get the best out of your butcher block for years to come.

Placement / Layout

Most cooks prefer an area between the cooking surface and the sink for the butcher block work area. The size of the work area is a matter of personal choice. When properly located, the butcher block will receive all the knife marks and hot pots that can typically blister laminate surface.

Request a Quote

Get a Free Prompt quote

WHAT DO YOU GET FOR THE PRICE?

Prices listed are for rough lumber, sold random width, and random length. The lumber is manufactured to produce the best possible appearance while conserving the maximum usable product of the log. For orders requiring specific widths, lengths, and color, please contact us for a FREE estimate.

DETERMINING YOUR PRICE LEVEL

The footage of different species on the same order may be accumulated to determine price level. Ask us about special pricing on bunk (1000+ BF) quantities of any one specie. Prices and availability subject to change without notice.

MEASURING KILN DRIED LUMBER

Kiln dried lumber from printed prices is measured after kiln drying and sold on net tally. No additions are made to cover the shrinkage which takes place in kiln drying. All thicknesses less than 1" are measured in surface feet.

PRICING FOR SPECIAL SIZES

Printed lumber prices are for random width and random length lumber unless stated otherwise. We are happy to supply special widths and/or lengths for an additional nominal fee. Please contact us for availability and prices on special sizes.

OUR GUARANTEE

Your lumber purchases are fully guaranteed to be properly graded, measured and machined. LLJ does not guarantee products against loss or damage in transit due to circumstances beyond our control. To receive full credit for a returned package, the package must be in the same condition in which it wasreceived.